Ontime and Stressfree Development with Money Back Guarantee... Click to know more

Ontime and Stressfree Development with Money Back Guarantee... Click to know more

Metal Parts - Custom

Design with Low MOQ

93% First Trial Approved

Prototype and Production Dies

Dedicated CRM for Regular Updates

One Stop Solution - Design || Tooling || Production

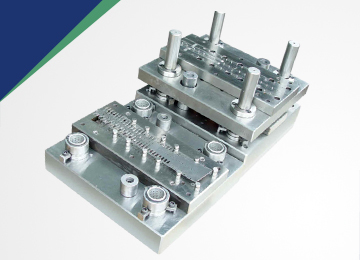

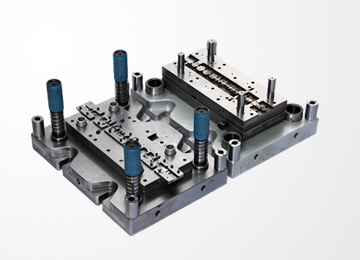

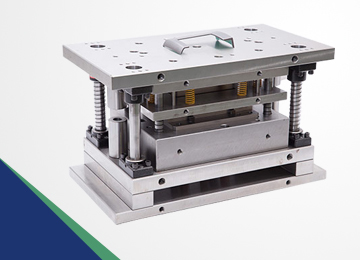

If you are looking for Stamping Dies Manufacturing with a reliable and competent service, you are at the right place. At Krishani Product Development, dies are manufactured with expertise as our die makers are proficient, experienced, and well-versed with the latest technologies and innovations. We create Progressive Dies that are well-made by our expert technicians and designed to make parts that are as per your design specifications. Our dies have a long life and have a smooth production process with low maintenance.

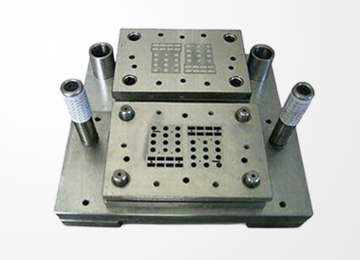

At Krishani, we bring your ideas to reality! If you don't have a CAD file, we will design the part as per your specification and then develop the dies to produce the parts. With our Metal Stamping Tooling, we do cost-effective metal stamping, which involves bending, punching, embossing, coining, etc, to shape the metal. Our expert CAD designers and die makers take care of each detail of your metal stamping die part. Metal stamping processes like Progressive Die Stamping involve operations like bending, punching, embossing, coining, etc., depending upon the design of your part. Our expert diemakers take care of each detail of your metal stamping part.

At Krishani, we can handle both small-scale and large-scale production runs. Whether you are starting a new business and need a few hundred units, i.e., a low MOQ (minimum order quantity), or tens of thousands, we have the expertise to meet your needs. You can order larger quantities later when you have tested the market and are good to go with full force!

Discuss your Requirement with our Experts

670+ clients served, Share your requirement in detail to get accurate quote

Great Experience!

At first, we hesitated to collaborate with Krishani Product Development because of their development center in India. However, any concerns vanished swiftly. Their thorough understanding of our requirements and transparent communication overcame any geographical barriers. They have not only met but surpassed our expectations by delivering high-caliber products ontime. They are not only manufacturers but they proved to be invaluable development partners. We would highly recommend their services to anyone looking for product development.

Derek Smith

Production was Really Good...

Hi, my name is Drew and I recently worked with Krishani Product Development, and it was a pleasure working with them. They were always easy to get in touch with, quickly answering my questions and concerns. Their regular updates and transparency at every stage made the product development journey smooth and gave me "Peace Of Mind"

Drew Simpson

Fully satisfied with the service

We worked with Krishani for the first, and DEFINITELY not the last time. Their team was a huge help and took the time to walk me through different rubber and silicone materials and their benefits and suggested the grade best suited to my product. It was a new development and I am fully satisfied with the service and the product they developed. I couldn’t ask for more.

Clark Brewer

We also make Automotive Stamping Dies that are suitable for various applications.

Are you looking for a tooling custom-made to produce precise metal parts with perfect quality? At Krishani, we provide you with full support from design to manufacturing. We will provide you with the best metal stamping tooling services in the market. Increase your productivity with progressive dies. Provide us with a CAD file we will do the metal stamping tooling for you. Our well-made designs ensure the high accuracy of the produced parts. Our designs hardly face any rejection. We prioritize efficiency above all to give you cost-effective solutions. We have a long-term vision that understands the nuances of metal stamping tooling. You can expect perfect tooling that is highly durable and requires low maintenance costs in the future.

Guys at Krishani are very professional in what they do. We got custom silicone molds developed as per our design and they even suggested modifications in our design which best suited our requirement. They are one stop shop for consultancy, designing, tooling, and production. Great Experience!

Derek Smith

A stamping die is a kind of tool that is used in manufacturing to cut and form, and shape metal sheets into the desired profiles. The cutting and forming section of the die we make is typically made from tool steel, which is basically hardened steel; it can also be formed by carbide and various other hard and wear-resistant materials.

If you have any requirements, feel free to contact us at +1 647-294-5240 OR info@Krishani.com to discuss your requirements in detail. Our Engineers & Designers will understand your requirement and will suggest the Tool Design, the kind of material suitable for mold making and production along with the number of cavities required depending upon your future production projection. At Krishani Product Development, we are happy to serve you!